Factory inspection is a crucial activity for every business. So, how is this work carried out? What is the purpose of the inspection process? Are the costs high? In the article below, A Chau will answer all the inquiries businesses may have, clearly and comprehensively.

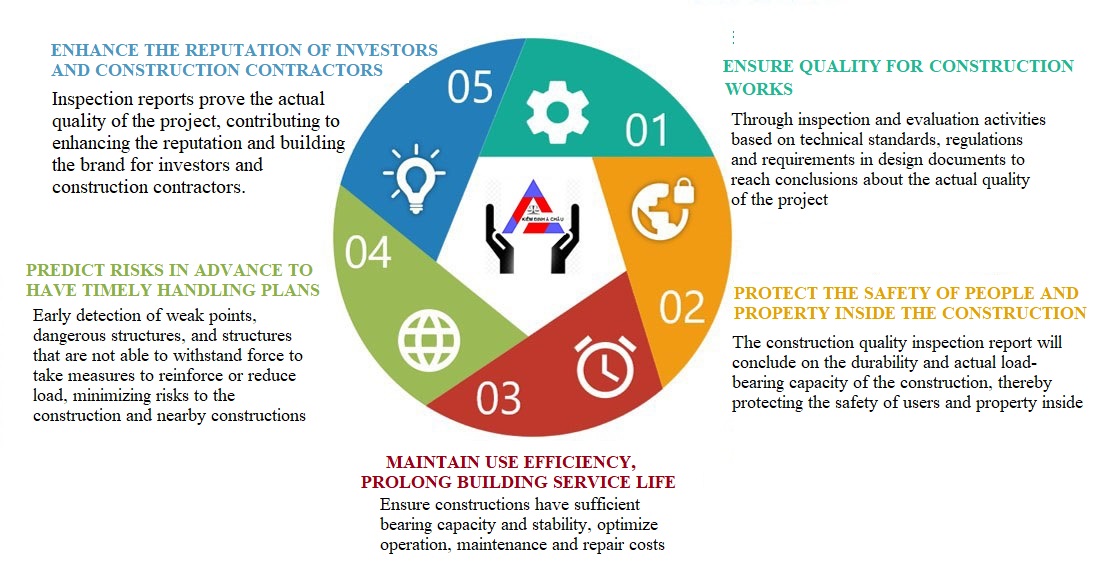

1. Why is factory inspection necessary?

Factory inspection is the process of examining and accurately assessing the quality of the factory based on technical standards. This includes structural components and load-bearing constructions. This task is typically carried out by specialized organizations licensed by the Ministry of Construction.

Businesses are required to conduct factory inspections according to regulations for the following reasons:

• To ensure absolute safety for activities conducted in the factory.

• To comply with construction law regulations.

• To protect the company's assets.

• To enhance work efficiency.

The inspection schedule is based on Circular No. 10/2021/TT-BXD (Section 3, Article 17) with the following specific guidelines:

• Initial quality inspection: After approximately 10 years from when the construction begins operation and use.

• Subsequent inspections: Conducted every 5 years according to regulations.

According to TCVN 9343:2012 (Section 5.5.3), the inspection cycle is regulated as follows:

• Specially important constructions: Inspection every 2 to 3 years.

• Constructions with high operational frequency: Inspection every 3 to 5 years.

• Other industrial and civil constructions: Inspection every 5 to 10 years.

• Factories affected by marine climate corrosion or chemicals: Inspection every 1 to 2 years.

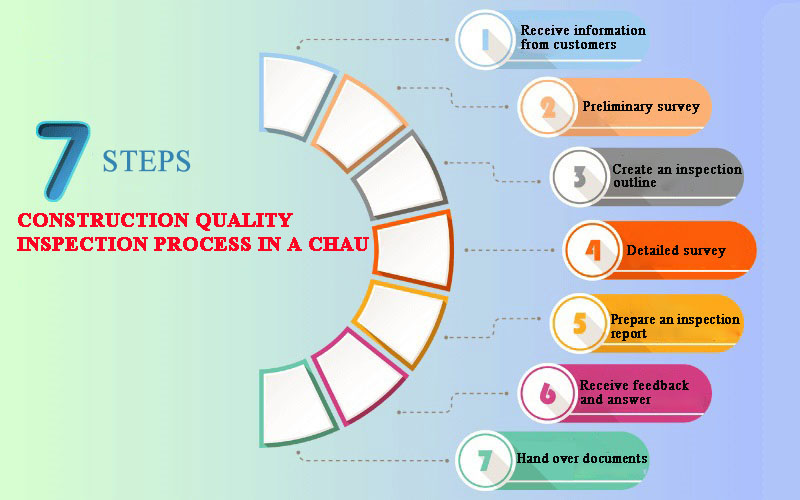

Step 1: Receive information and inspection requests from customers

Investors and customers who need inspection could contact A Chau. Through discussion, A Chau will understand the needs and purposes of the inspection and some basic information about the project: Scale, location, structural characteristics, etc.

Step 2: Preliminary survey

The purpose of this step is to collect more detailed documents about the construction. A Chau implements direct observation to make a preliminary assessment of the level of damage, diagram, type of structure to build an inspection outline and quote the cost of implementation.

Step 3: Create an inspection outline

After understanding the needs, inspection purposes and actual quality status of the project, A Chau will develop an inspection outline including inspection following information:

The investor or customer will evaluate the inspection outline (with inspection cost quote) as a basis for selection and signing off the inspection contract.

Step 4: Detailed survey

After inspection outline been approved by investors, A Chau will assign a team of engineers and architects with appropriate experience and capacity to conduct a detailed survey of the project structure with the following basic contents:

Step 5: Calculate, evaluate the quality of the project and prepare an inspection report

Based on the results obtained during the detailed survey, we synthesize and analyze the data, calculate and evaluate the actual quality of the construction.

Step 6: Receive feedback and answer inquiries from customers

After completing the inspection report, A Chau will send a soft copy of the inspection report to customers and investors for preview and answer inquiries (if any) from investors and customers. After agreeing on the results, an official publication will be issued with a confirmation stamp from A Chau.

Step 7: Hand over documents, finish inspection process

A Chau will hand over the inspection report according to the quantity required in the contract, carry out contract liquidation procedures, and finish the work.

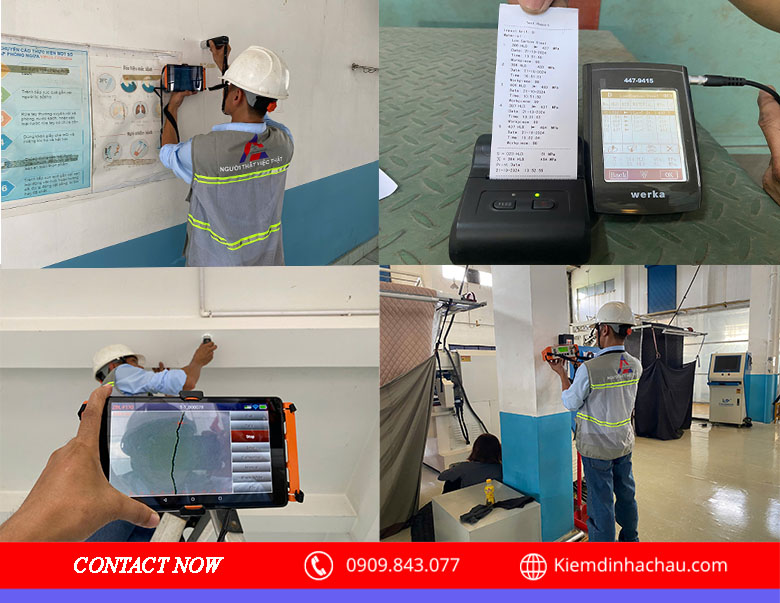

During the factory inspection process, depending on the purpose of the inspection and the structural characteristics, different tasks and corresponding methods will be applied. This article outlines some basic methods used in factory inspection process:

a) Inspecting the current state of the construction:

Structural engineers will perform visual observations and use equipment such as cameras, steel rulers, calipers, and crack-width measurement devices to assess the condition of the construction.

b) Inspecting the geometric dimensions of components:

This is carried out using direct measurement methods with tools such as steel rulers, calipers, and ultrasonic thickness gauges for metals.

c) Inspecting the quantity and diameter of reinforcing steel:

This is performed using ultrasonic testing methods or by direct inspection through chiseling.

d) Testing the concrete strength:

Destructive method: Core sampling is conducted on-site, and the samples are compressed in a laboratory to determine the concrete strength.

Non-destructive method: Use a Matest rebound hammer to determine the concrete strength.

e) Inspecting the vertical alignment of pillars and deflection of beams, floors, and roof trusses:

This is performed using surveying methods with a Leica electronic total station.

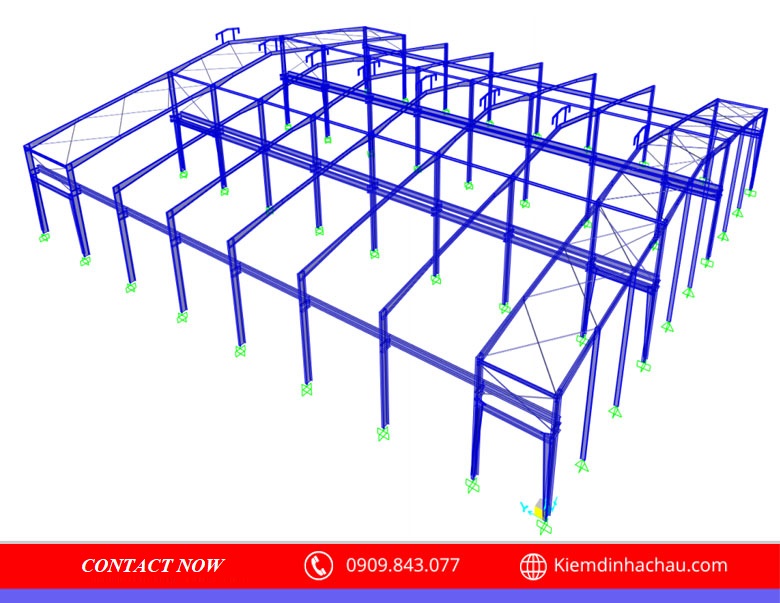

f) Calculating and assessing the load-bearing capacity of the structure:

With the support of structural software such as Sap, etabs, safe, etc., models are created to determine internal forces within components. This aids in evaluating the load-bearing capacity based on current regulations and standards.

6. Cost of Factory Inspection

According to Article 5 of Decree 06/2021/NĐ-CP, the costs of factory inspection are determined as follows:

Cost determination

• For projects involving state budgets: Inspection costs are calculated by preparing an estimate based on the scope of work, norms, and unit prices as specified by regulations.

• For private projects: Costs are determined based on the scope of work and private market unit prices.

Who pays for inspection costs?

• During construction: Contractors are responsible for inspection costs if the inspection results confirm that the fault lies with them. In other cases, the party requesting the inspection will bear the full cost.

• During usage: The owner or the operating unit of the factory is responsible for covering the inspection costs. If the inspection confirms faults caused by any involved party or organization, that party must bear the inspection costs.

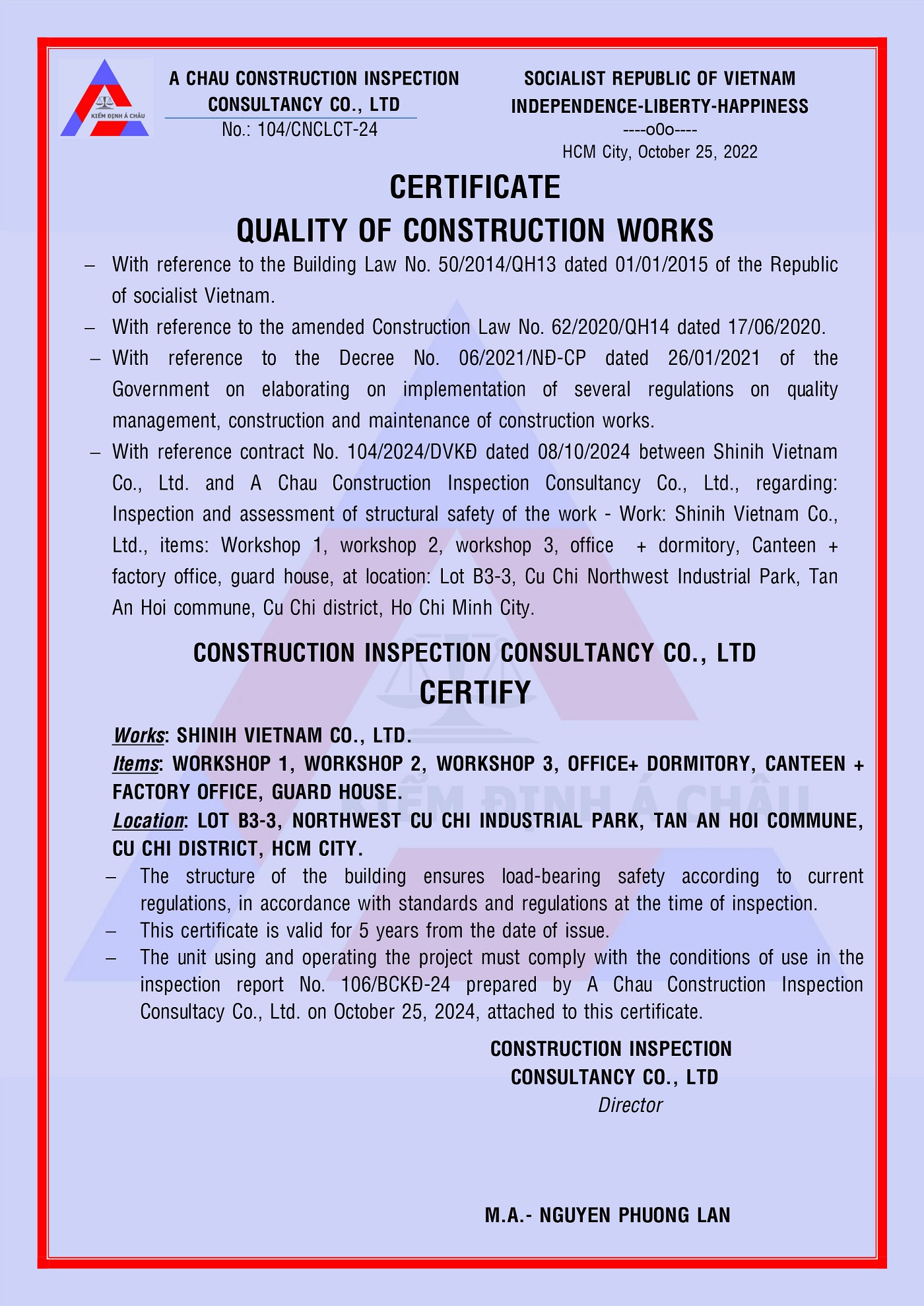

According to Clause 2, Article 112 of the Construction Law issued on June 18, 2024, businesses have the right to hire companies with sufficient operational capacity to inspect the quality of their constructions. These companies follow inspection processes based on standards set by the Ministry of Construction, ensuring accurate and legally compliant results.

Additionally, reliable inspection companies possess licenses and certifications issued by the Ministry of Construction, providing businesses with confidence in their expertise and legal qualifications during the inspection process.

7.2 Ensuring basic professional standards

Choosing a reliable inspection company ensures that professional requirements are met effectively. They have experienced engineers in the field of inspections and utilize modern equipment to comprehensively assess the structural condition of factories. Inspection reports are presented clearly and in detail, ensuring legal compliance.

7.3 Ensuring objectivity and integrity

A professional, experienced, and reputable inspection company in the construction industry delivers quick, objective, and honest inspection results. The company commits to providing businesses with transparent and impartial information.

For A Chau, credibility is the guiding principle of our operations. We ensure top-quality service when you entrust us with your inspection needs.

7.4 Ensuring timeliness and progress

An inspection process carried out by a reputable company ensures that the work is completed on time without affecting the project schedule. By implementing scientific and reasonable inspection procedures and methods, the inspection process is completed efficiently. If any issues arise during the work, the company will flexibly adjust the schedule to ensure progress is maintained.

Conclusion

You have just reviewed detailed information about our factory inspection services. A Chau is proud to be a trusted provider of inspection services favored by numerous clients nationwide. We are committed to delivering high-quality services and the most optimal solutions for your business.

For more related services of A Chau:

• Construction project quality inspection

ID POST: OFF365